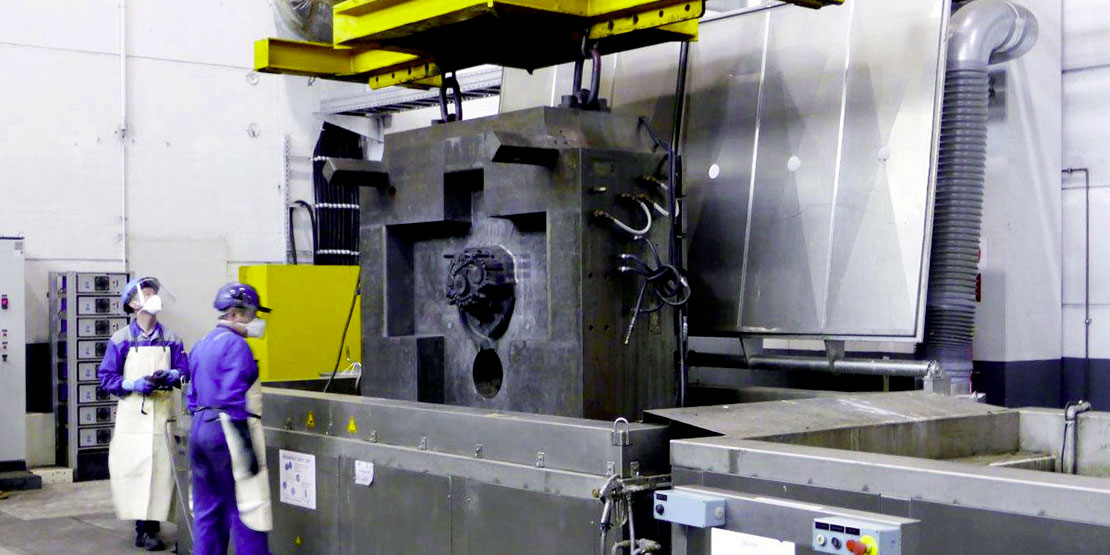

Ultrasonic cleaning for the foundry: die-casting, low pressure, corebox

Subcontractors of purchasing sectors – automotive, steel, handling equipment, industrial equipment, electrical equipment, aerospace, armaments, etc. – metal Foundry professionals are faced with polluting of metal molds or shells, particularly due to the presence of mold release solutions.

We have a standard range of machines and a proven process to meet your needs, whether for:

- ferrous metal foundry such as cast iron and steel.

- non-ferrous metal foundry: copper, zinc and alloys.

- light alloy Foundry: aluminum, zamac and other light alloys.

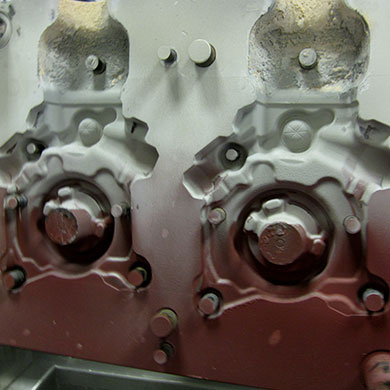

Aluminum foundry: Crankcase (before cleaning)

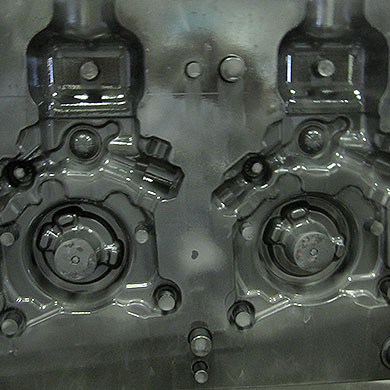

Aluminum foundry: Crankcase (after cleaning)

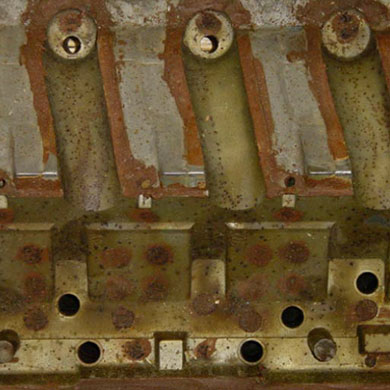

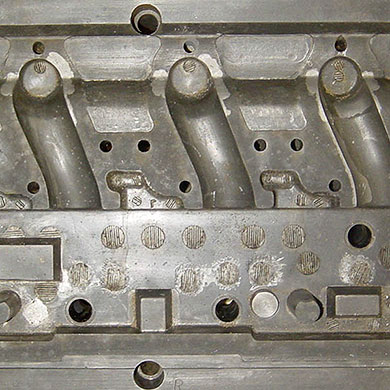

Foundry – example of molds before cleaning using a FISA process

Foundry – example of molds after cleaning using a FISA process

Foundry – example of molds before cleaning using a FISA process

Foundry – example of molds after cleaning using a FISA process

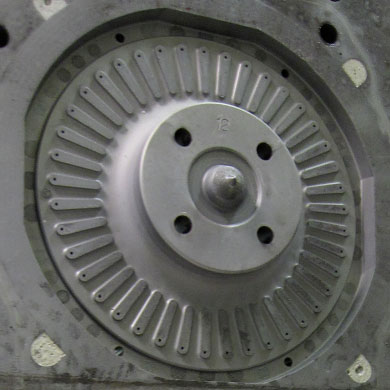

Foundry – corebox cavity for manufacturing clutch discs before cleaning

Foundry – corebox cavity for manufacturing clutch discs after cleaning

The advantages of the ultrasonic cleaning process for molds and tools

The ultrasonic cleaning process proposed by FISA offers most benefits for cleaning your molds and tools both technically and financially:

- non-abrasive technology,

- improved cleaning quality,

- increased shelf life for your molds and tooling,

- less time spent on maintenance,

- partial dismantling of molds,

- masked time working,

- lower running costs.