Ultrasonic cleaning to maintain molds and tools for injection/extrusion/compression of plastics and rubbers

If your business is thermosetting or thermoplastic injection, or you’re specialized in extruding plastics or rubber, you are faced with the permanent dilemma of how to maintain your molds, plates and tools, a key factor for producing high quality parts.

Mold release agents, material gases and residues are amongst the contaminants that must be removed without damaging integrity of the mold.

Plastics – extrusion die before FISA cleaning

Plastics – extrusion die after FISA cleaning

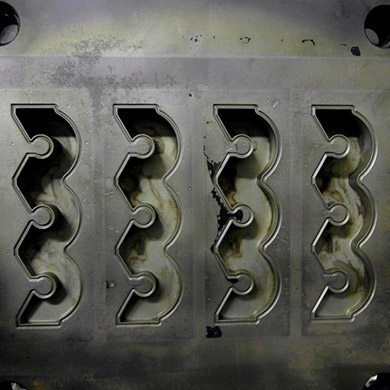

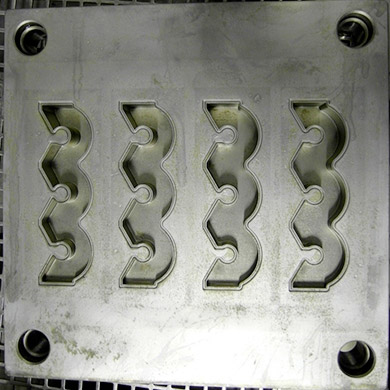

Rubber mold before FISA cleaning

Rubber mold after FISA cleaning

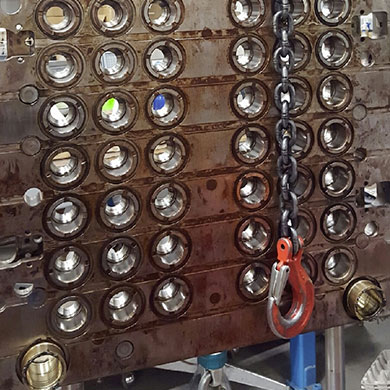

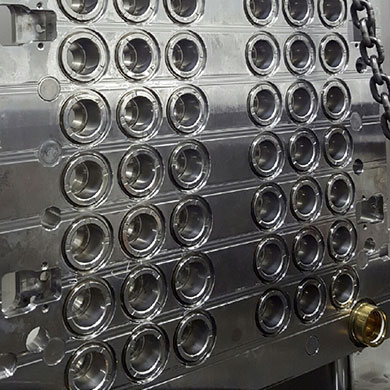

Plastics – cap closures mold before FISA cleaning

Plastics – cap closures mold after FISA cleaning

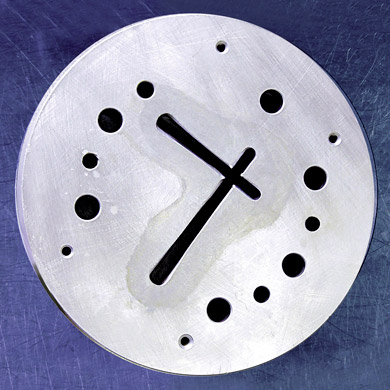

Plastics – cap closures mold before FISA cleaning

Plastics – cap closures mold after FISA cleaning

Advantages of our ultrasonic cleaning solution

The ultrasonic cleaning process proposed by FISA offers most benefits for cleaning your molds and tools both technically and financially:

- non-abrasive technology,

- improved cleaning quality,

- increased shelf life for your molds and tooling,

- less time spent on maintenance,

- partial dismantling of molds,

- masked time working,

- lower running costs.